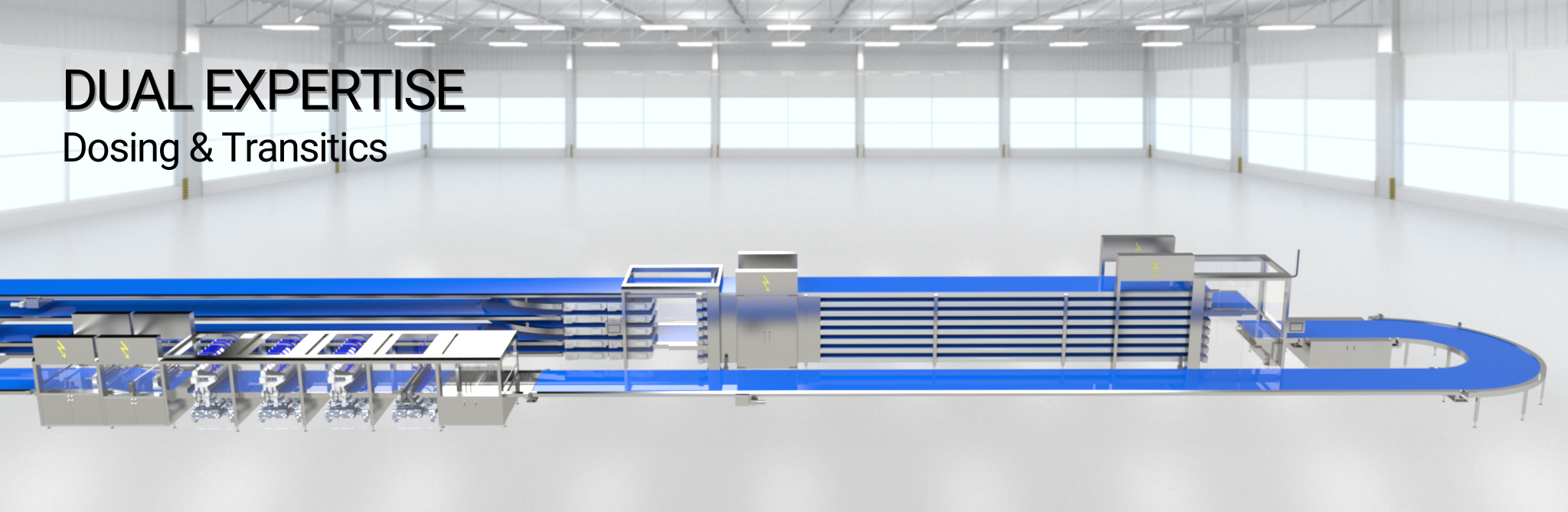

SG2C designs and constructs conveying, buffering, and flow handling solutions connecting processing machines (ovens, fryers, moulders, enrobers) to packaging equipment. The development of ingenious row-aligning systems also extends its benefits to dosing and injection machine feeders.

Expert in biscuits and bakery

SG2C was founded in 2006 building upon a 20-year experience within the former French company SOGEM FL. Subsequently, SG2C acquired not only the brand but also all associated drawings and patents.

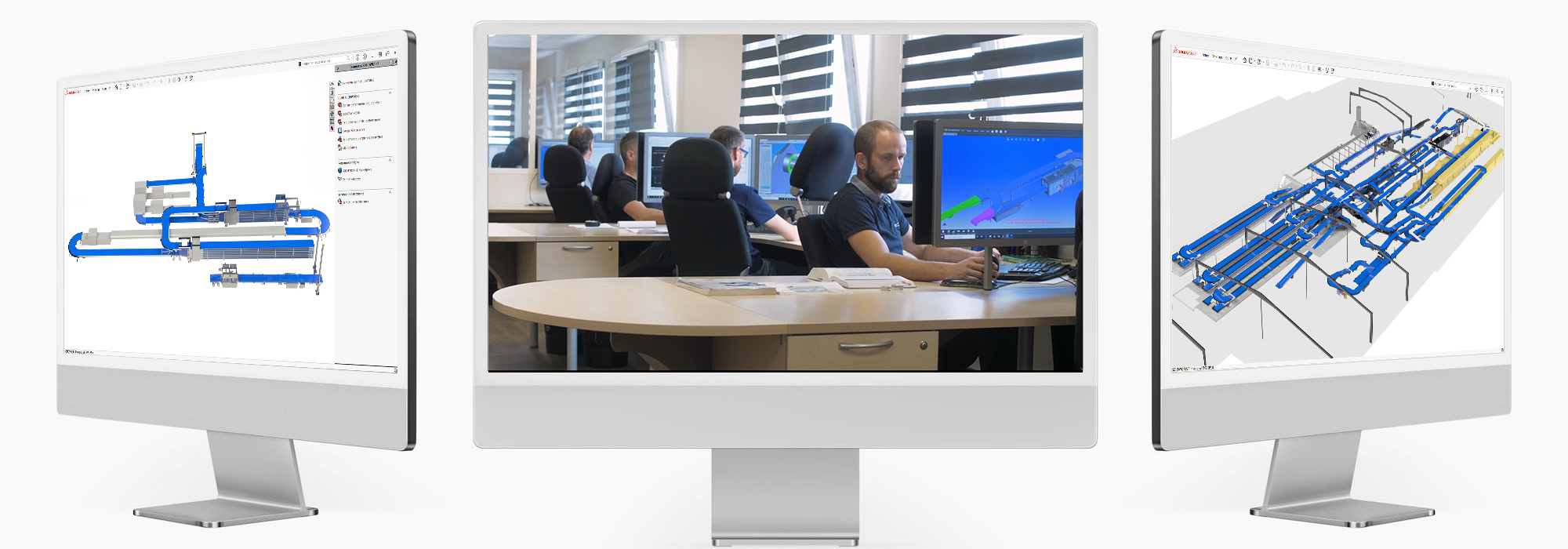

The designs were completely reworked, considering the user’s needs in mind. Introducing innovative concepts such as the compact, non-contact and guideless “Surf Belts” realignment conveyors.

The handling of small and fragile biscuits at high speed requires a high accuracy level and represents a valuable expertise that can be applied to many other products.

Efficient, innovative solutions

Snacking products are becoming more sophisticated with the addition of chocolate, causing their cost to rise due to ingredient inflation. Manufacturers are no longer willing to tolerate production wastes. Instead, they prefer high-performance buffers and equipment with options that ensure high efficiency while requiring minimal operator supervision. The SG2C range fulfills all these needs, offering flexible, multi-format and user-friendly solutions that also facilitate the seamless incorporation of unexpected marketing recipe innovations.

Hygienic by design

Food scandals are frightening and quality controls are on the increase. Since a long time SG2C has taken into account these growing cleaning concerns by standardizing the sanitary design with easily removable rollers and implementing cleaning in place for our dosing heads. Moreover, we have been exclusively building our systems in stainless steel for over 10 years, eliminating guides and incorporating various other measures.

Optimizing your layout

The biscuit industry is a complex production process, involving various tilting systems between ovens and different types of packaging equipment. The challenge also lies in solving critical space restrictions associated with long cooling times, which can require up to 200 meters of conveyors per line, installed overhead or on multiple levels. SG2C brings all its experience and the numerous advice, making a significant difference in project management.

Objectives achieved with satisfied customers

The France is dynamic in innovation and its know-how is recognized internationally.

SG2C has been equipping established industrial customers and has had the privilege of assisting several craftsmen who successfully embraced automation.

SG2C export over 50% of its solutions to major industrial groups, local companies, and our integrator customers.

Local services in North America are provided by our Canadian partner, ABF Systems.

We are also delighted to help our OEM integrator and machine builder partners in completing their process and packaging range, empowering them to offer turnkey solutions.