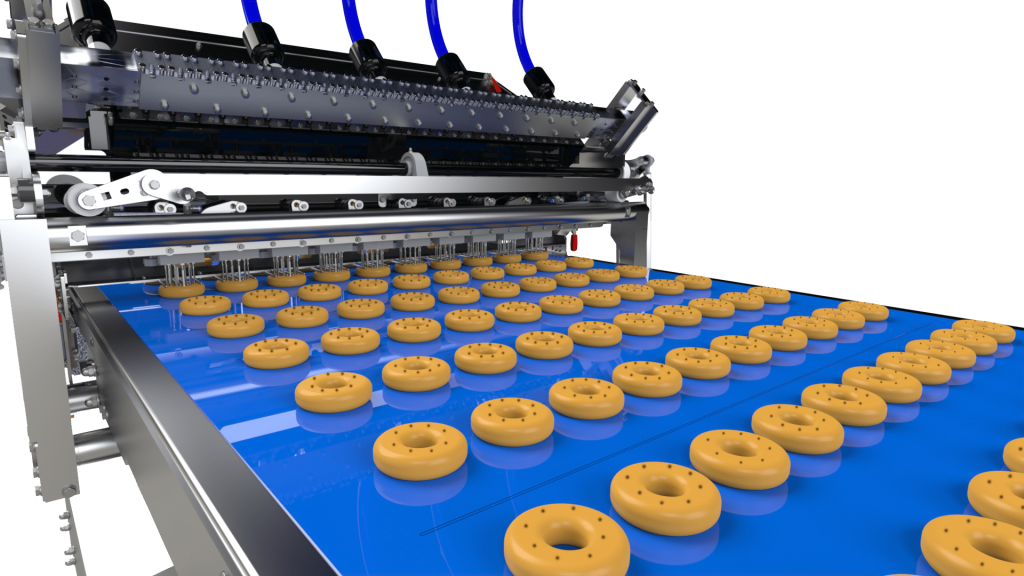

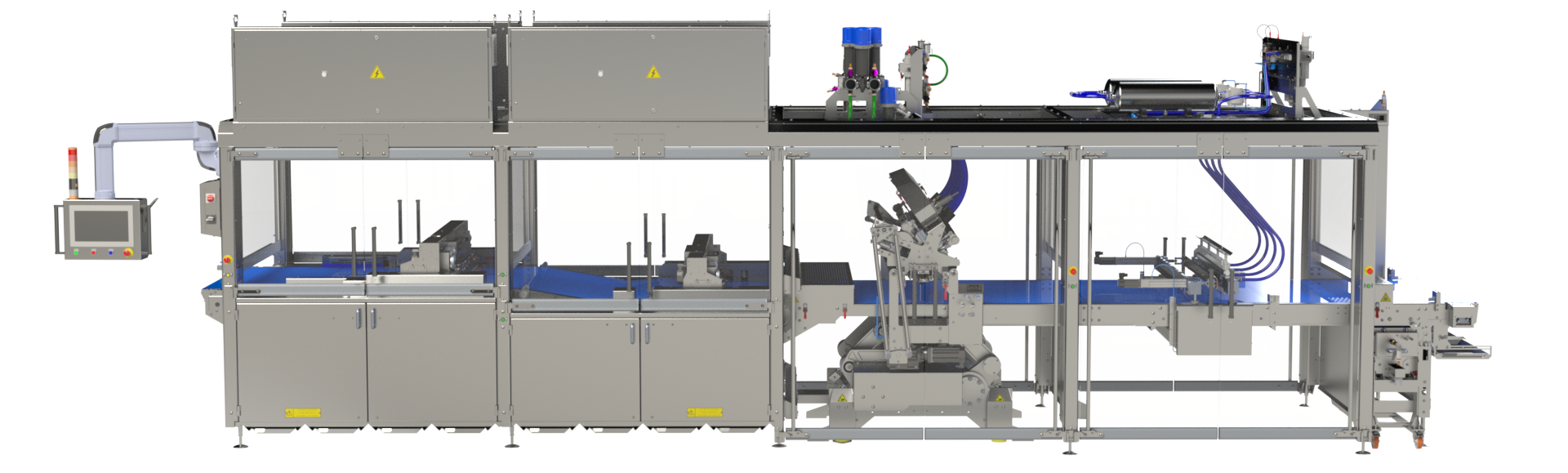

The dosing machines are fed by aligning systems without guides, minimizing tools, enabling rapid format changeovers and facilitating addition of unanticipated marketing innovation recipes. There is no longer a need for operator supervision while eliminating the risk of product jamming.

To enhance flexibility and productivity, non-dosed products can pass through the machine while the dosing head is being cleaned in place (CIP). Dosing machines can be equipped with two heads to dose different fillings, or to allow one head to be cleaned while the other is running.

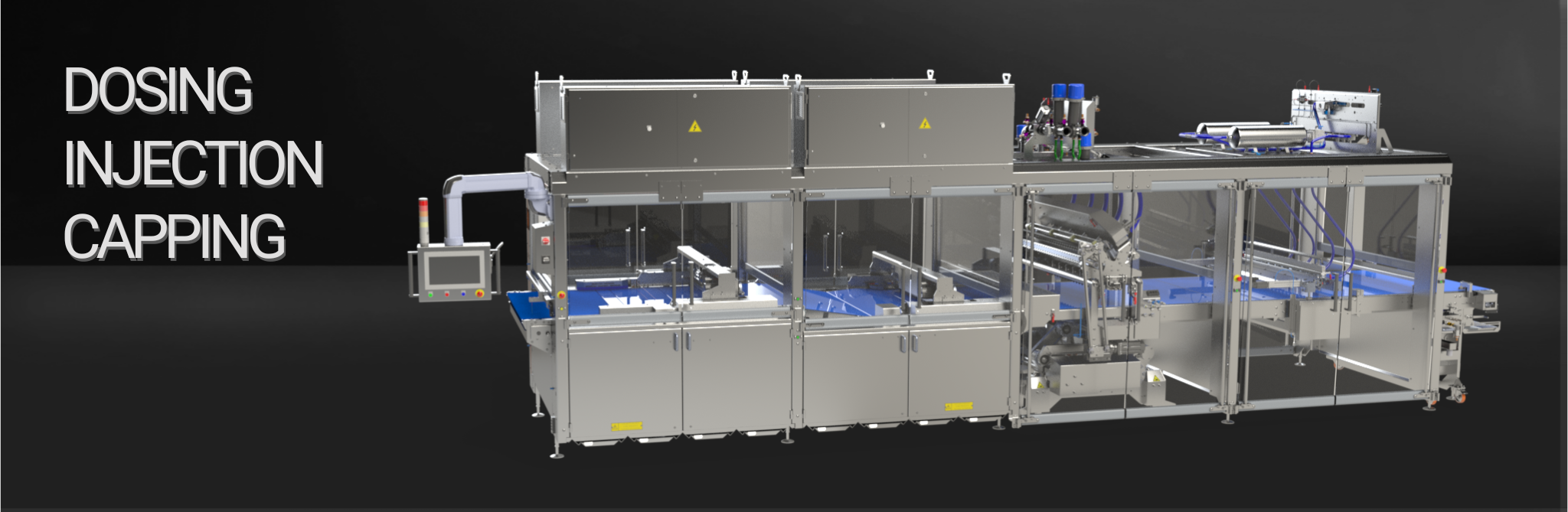

Dosing & Injection Machines

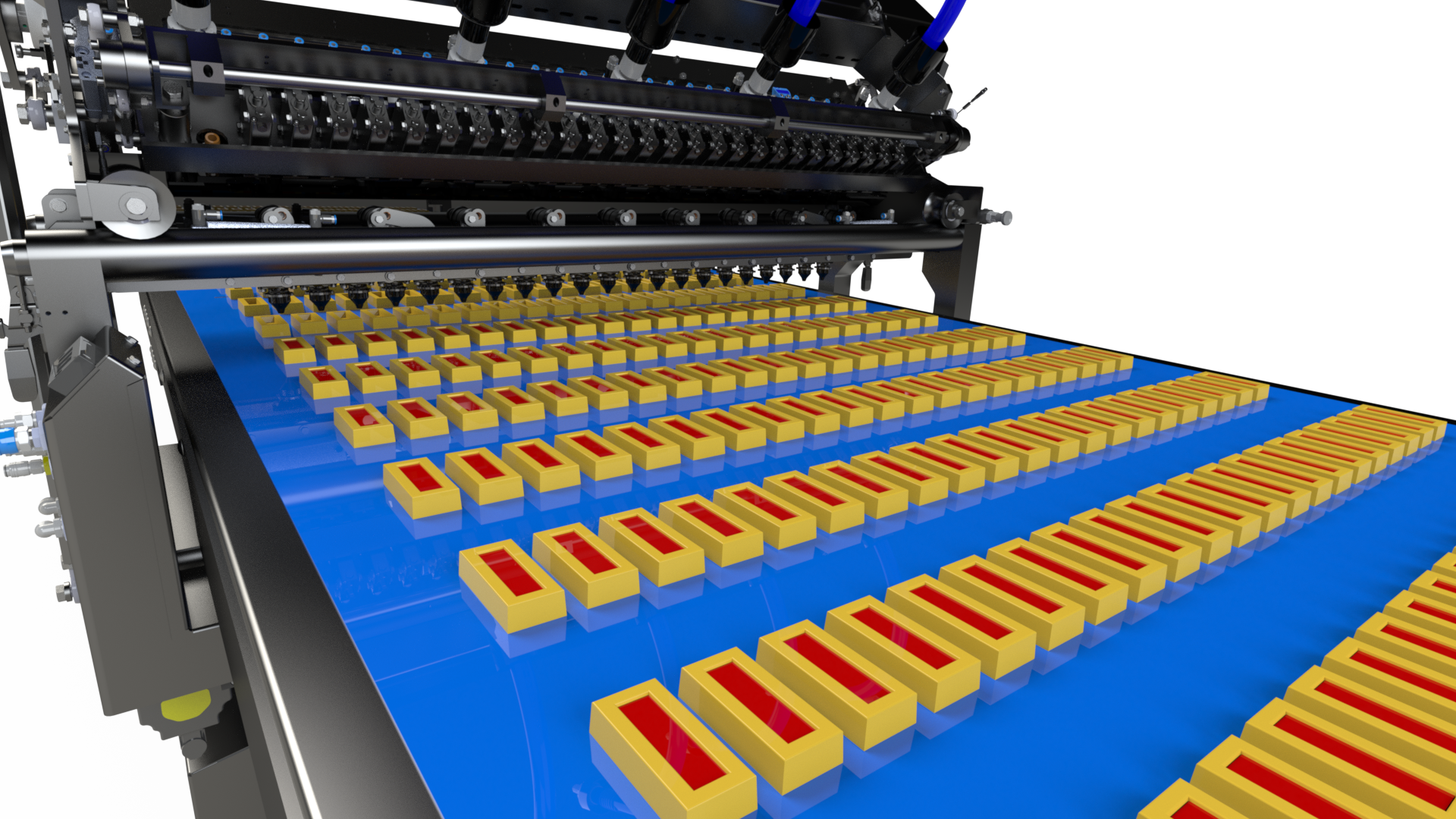

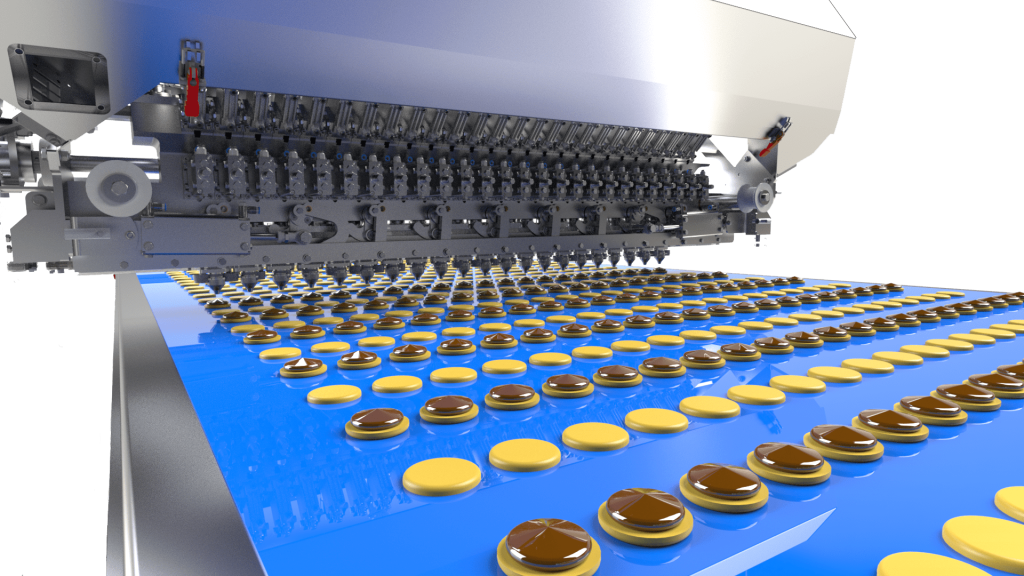

Volumetric dosing

High-precision dosing of chocolate, jam, caramel, ganache, etc. thanks to servo driven volumetric pistons capable of dosing from 2 to 50 grams per product.

Vertical and/or Horizontal injection

The same machine can be equipped with vertical or horizontal needle tools. Products are centered and carefully maintained in place during injection.

Smart functions

“No product, no deposit” to prevent depositing fillings on the belt and unnecessary loss of doses. Interchangeable nozzles and needles with adjustable center-to-center distances.

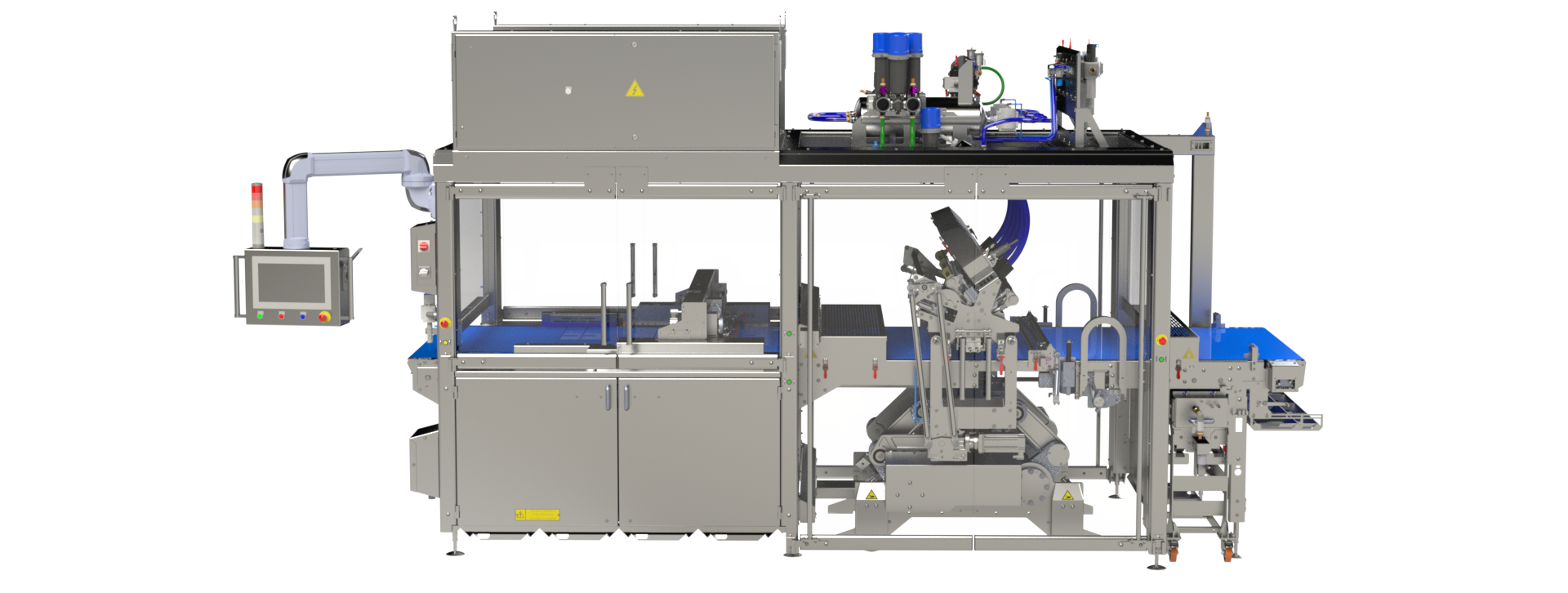

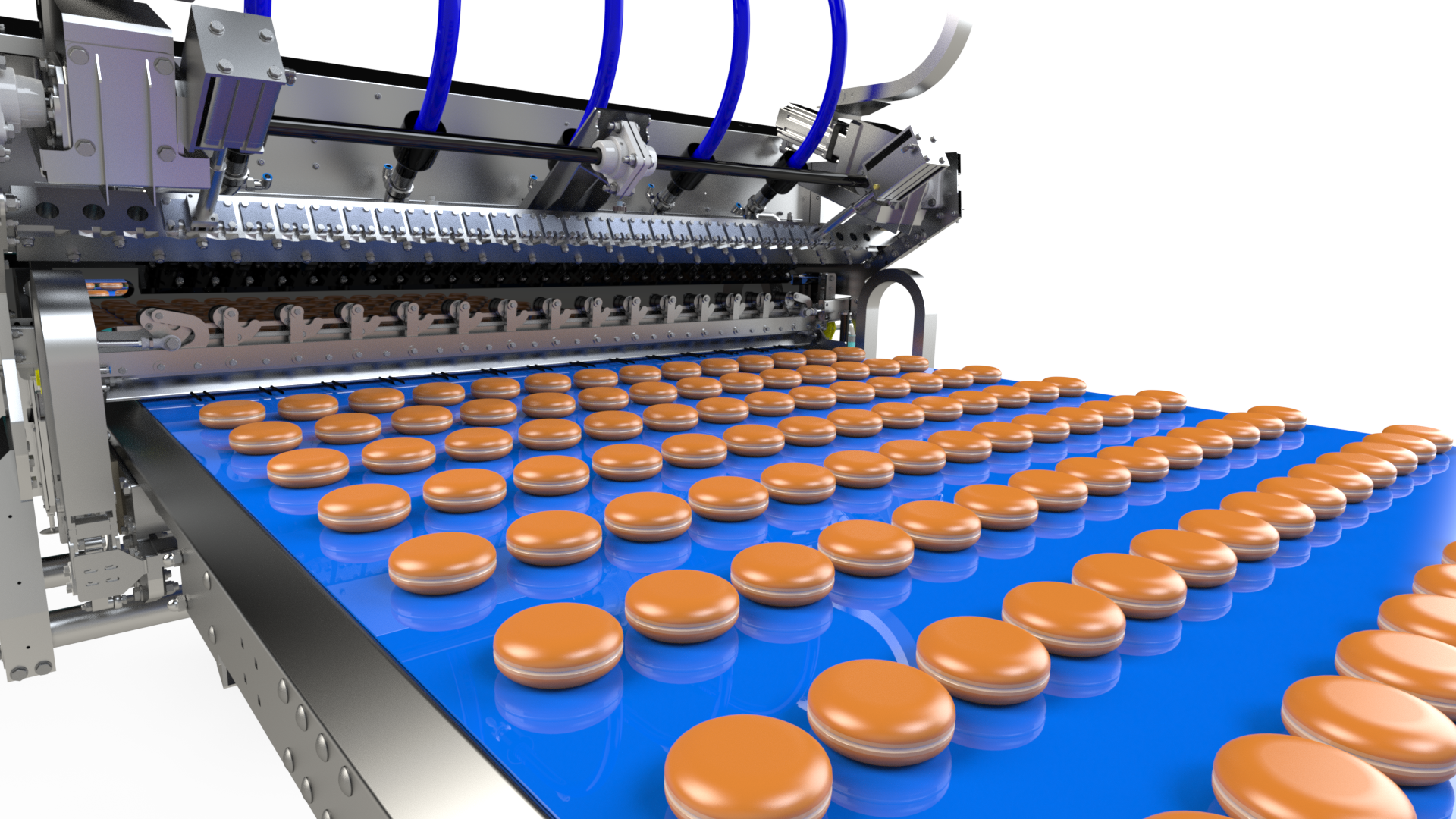

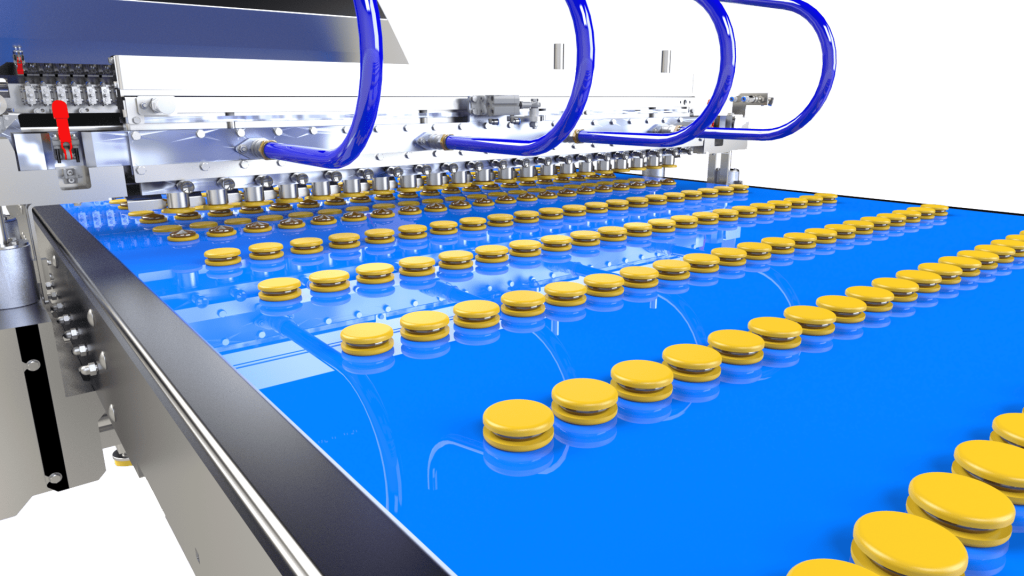

Capper Sandwiching Machines

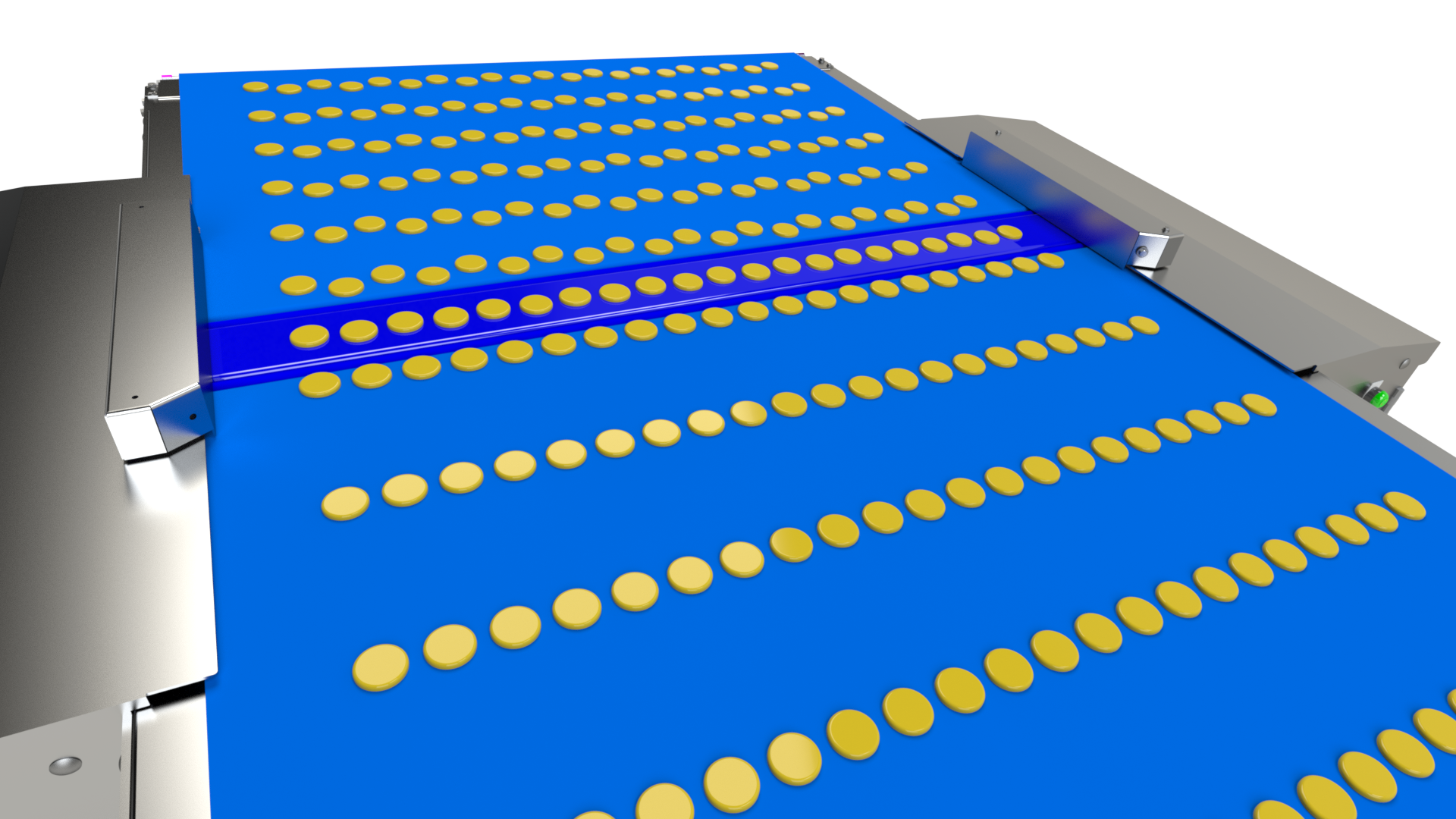

Realignment and positive turning

On-the-fly realignment without guides by

Surf Belts.

Recentering by a row aligner. Alternate row positive turning that accompanies the products, easy to by-pass.

Volumetric dosing

Individual pistons compatible with small doses and low temperatures. Fed by a tempering machine or a complete skid supplied with a buffer tank, pump and integrated CIP.

Capping head

Venturi suction head for assembling sandwiches with precise centering via

HMI. Integrated self-cleaning device that

can be activated without stopping

production.

Example of dosed or injected products with our solutions :

St Michel products - we are proud to provide dosing and injection solution for the entire range of biscuits and cakes produced by this French leader :

Mondelez products – Last but not least, we have as well successfully overcome various technological challenges for the world's largest biscuit manufacturer :