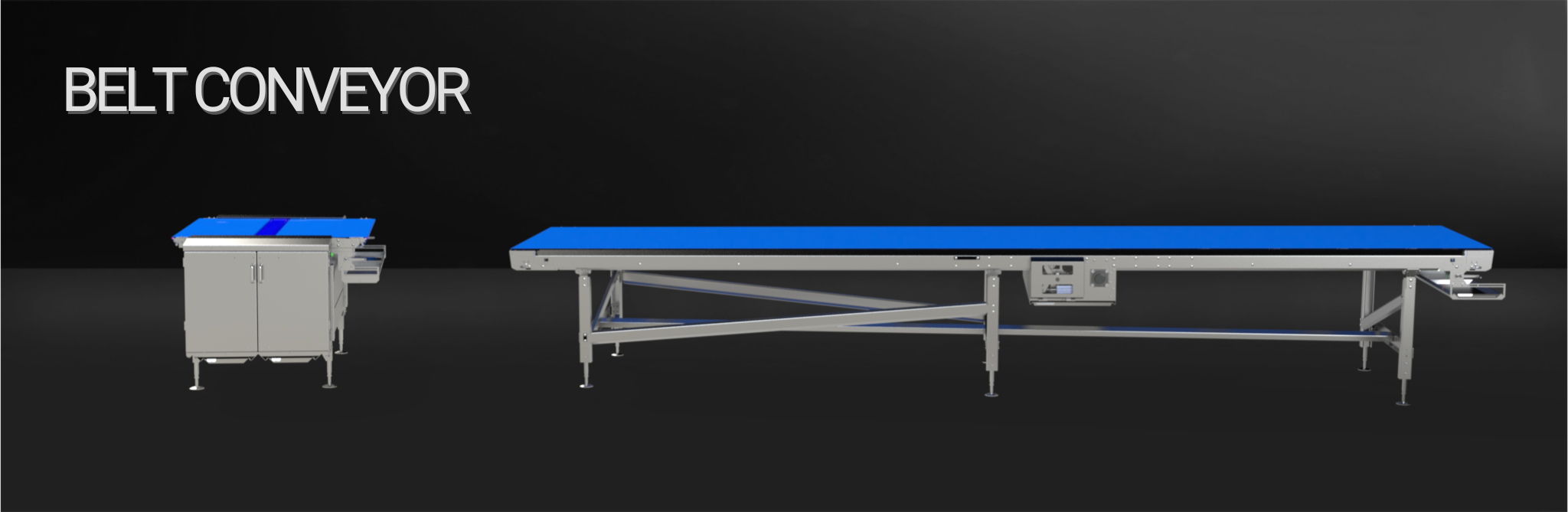

Conveyors have become key elements of production lines, offering 24/7 reliability, precise alignment, cleaning facility and minimal maintenance. SG2C has successfully standardized a wide range of stainless steel belt conveyors combining accuracy, hygiene and safety.

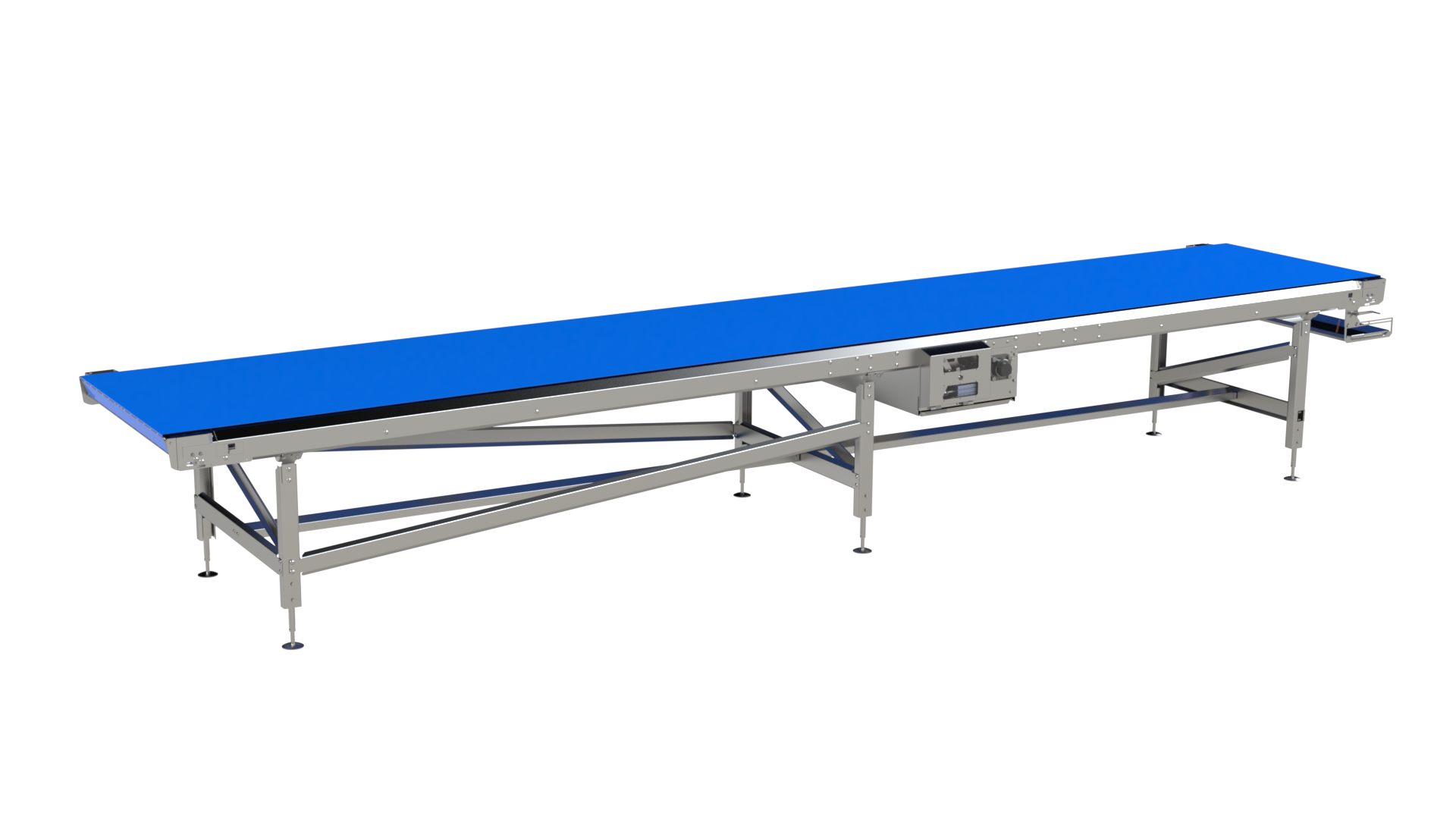

Standard conveyor

Width 100 to 2200 mm, length up to 80 meters, Ø15mm or Ø10mm end rollers.

Asynchronous or servo motors.

Efficient scraper with catch pan.

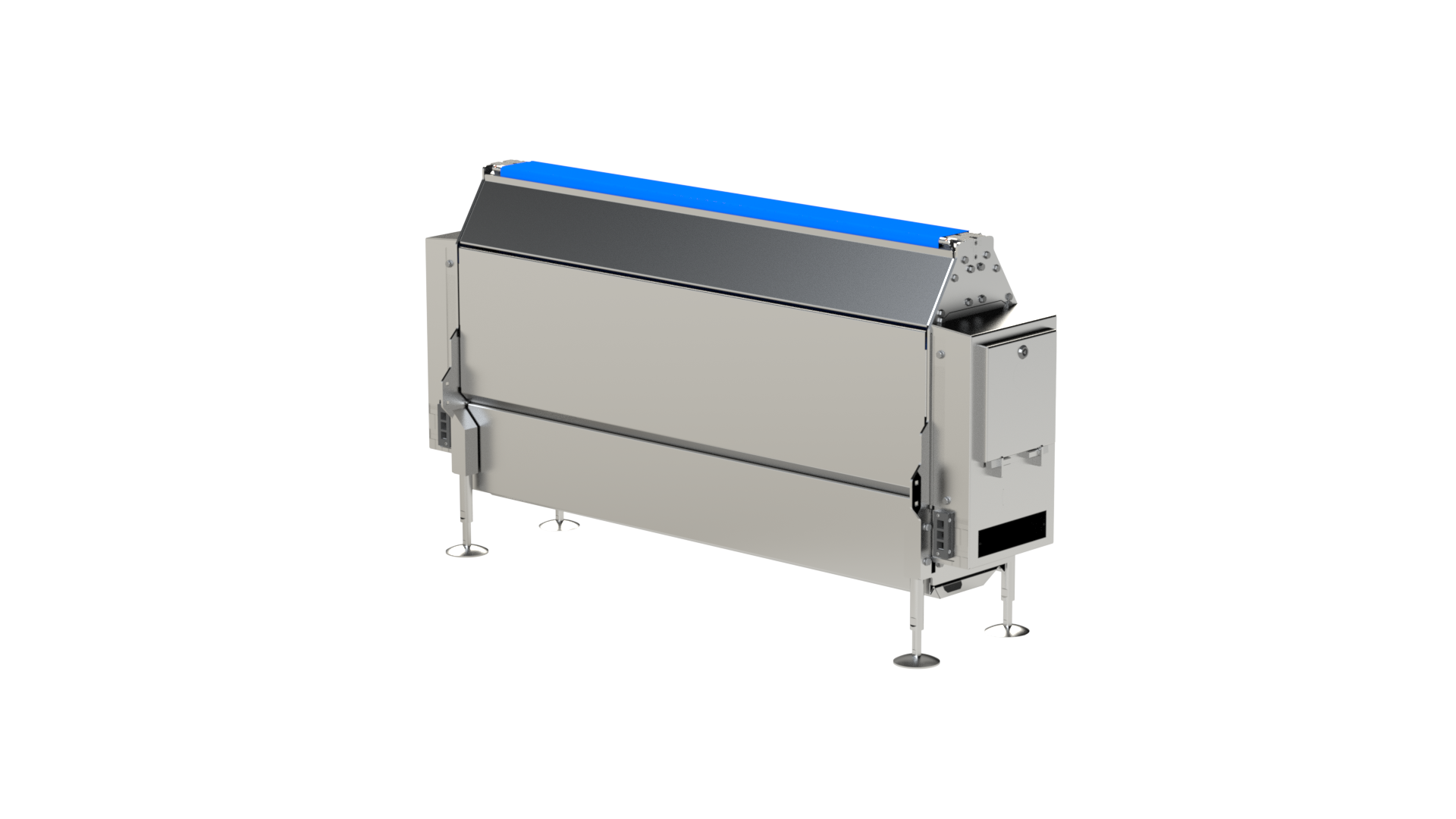

Angled conveyor

Conveyor with an angled nose ( from

20° to 60° ) to spread or reduce production flows.

It can also change the product orientation.

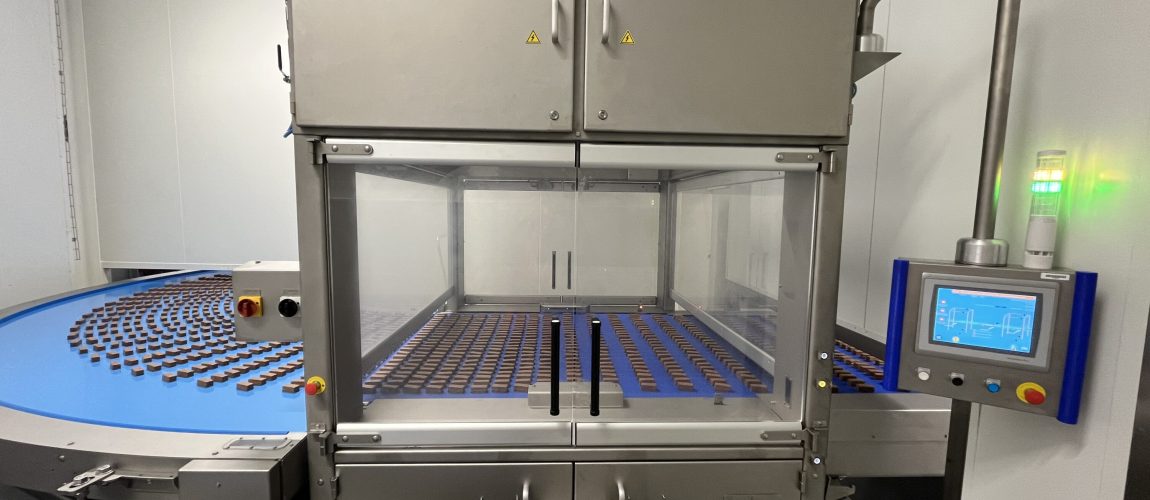

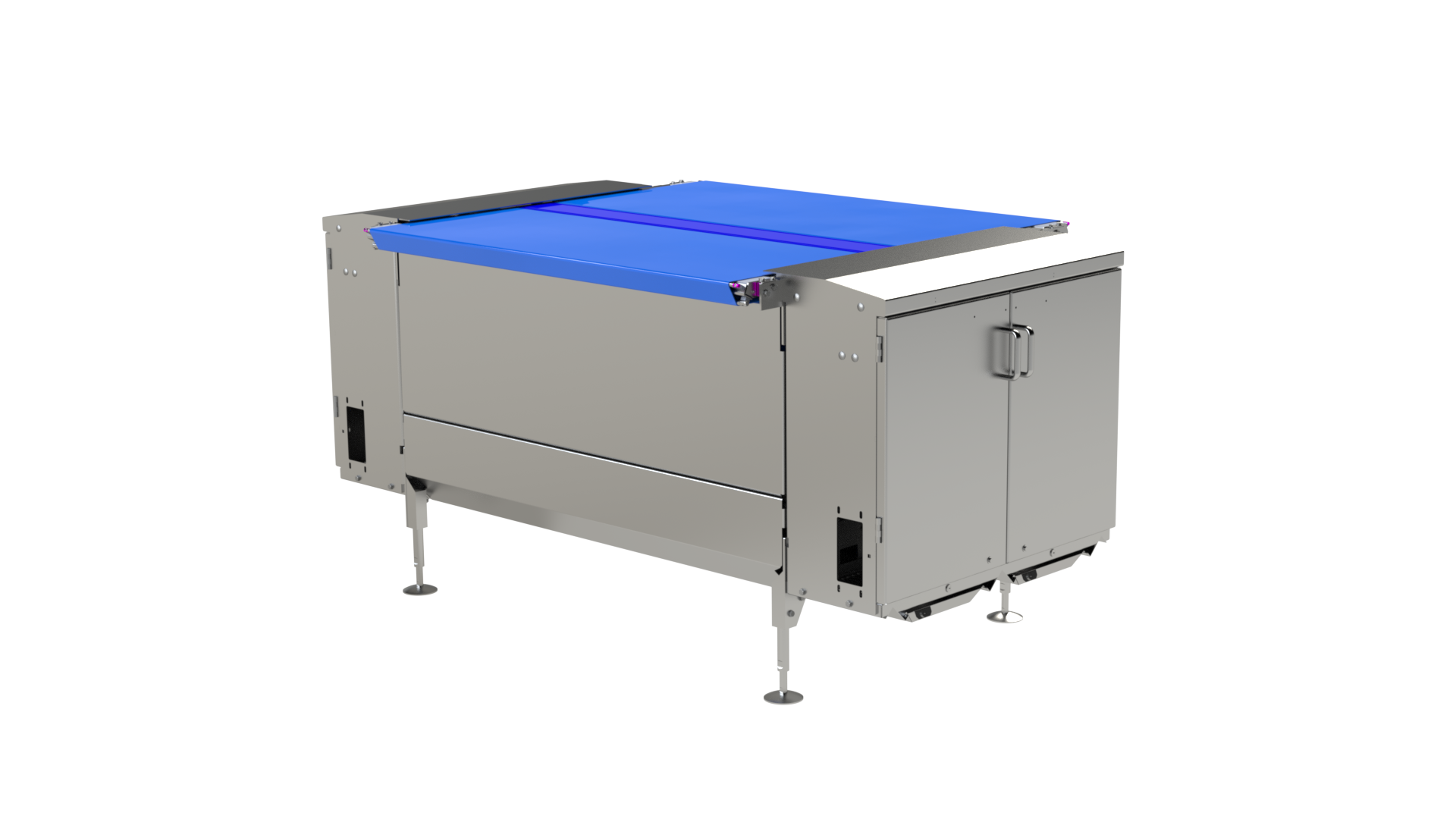

Pullnose or Tilting systems

Pullnose for rejecting non-compliant products or in case of line stoppage.

Manual or automatic tilting to change the product flow direction.

Compact conveyor

Smart and reliable design for lengths ranging from 100 to 1000 mm.

Precise belt tracking system with a quick-release solution.

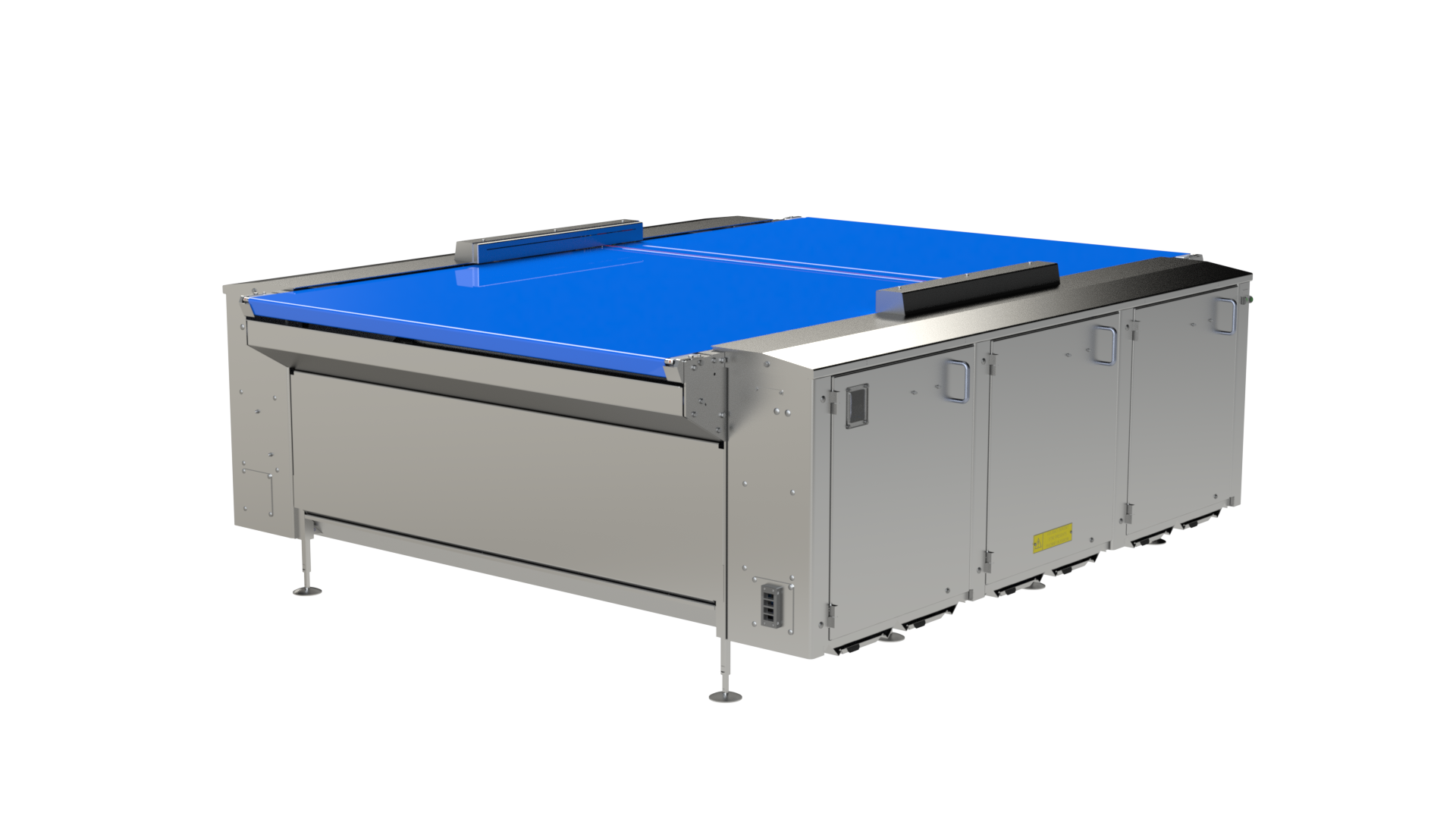

Surf Belts for realignment

Pioneer solution developed by SG2C in 2012 combining several short belts to realign products on the fly without contact.

Servo driven multi-format management.

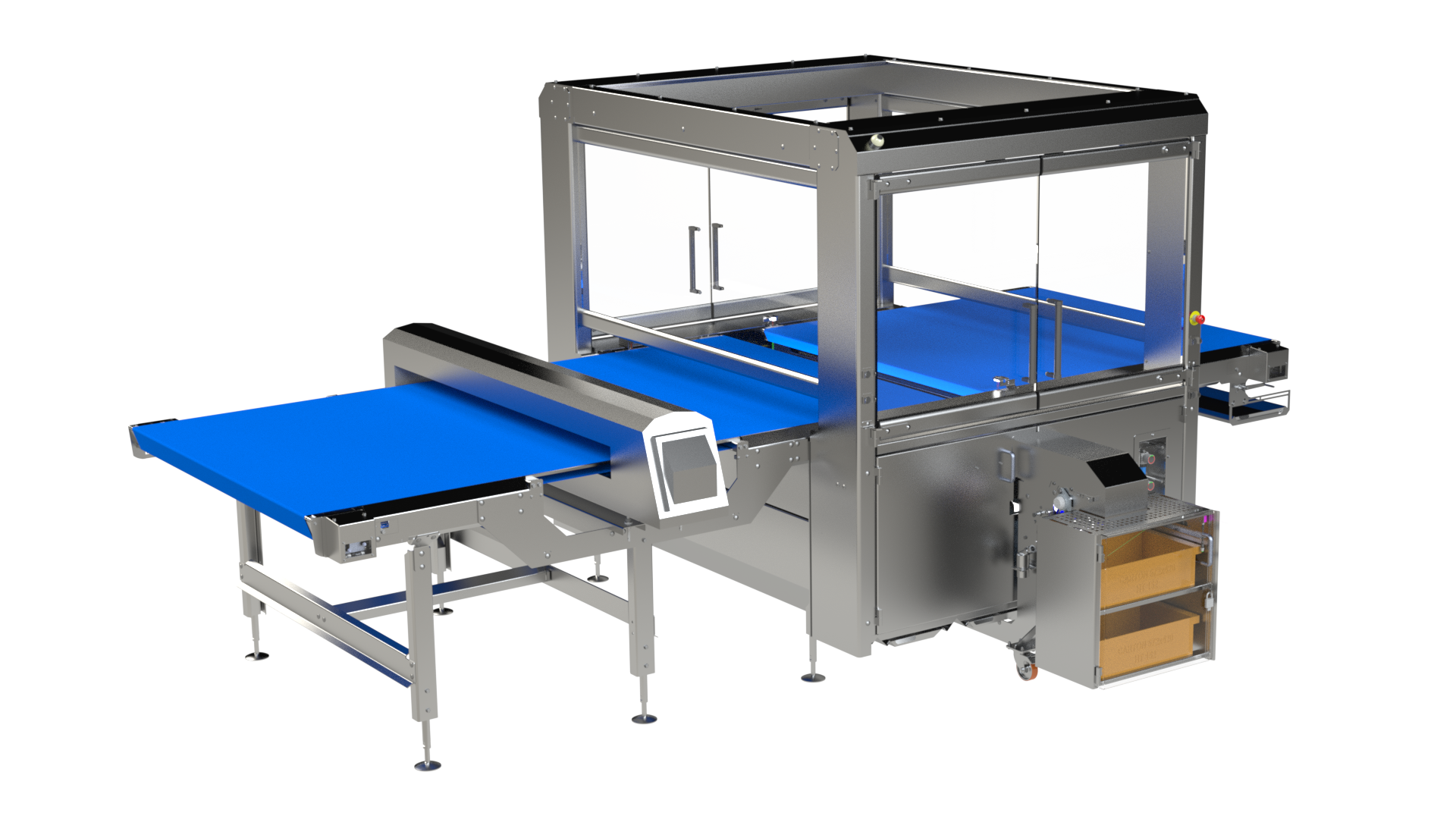

Double-pullnose

Dynamic system for row indexing, batch creation or transformation from continuous to discontinuous flow and vice versa. Staggered and random flow management is possible.